FCA US is made up of men and women from a wide variety of cultures, backgrounds and experiences. Our commitment to diversity helps breed innovation and accomplishment. Over the next few months, we’ll be taking a look at some of our most interesting and unique manufacturing employees working in a wide range of positions, locations and fields. Think of it as a “day in the life” of some of our most treasured assets — our people.

If you’ve ever wondered what makes a great car, it’s our people. FCA US has a total of 37 manufacturing facilities: 23 in the United States, six in Canada, seven in Mexico and one in Venezuela. That’s a lot of people working toward one common goal. Every one of our employees plays a unique role in making our manufacturing operations world class.

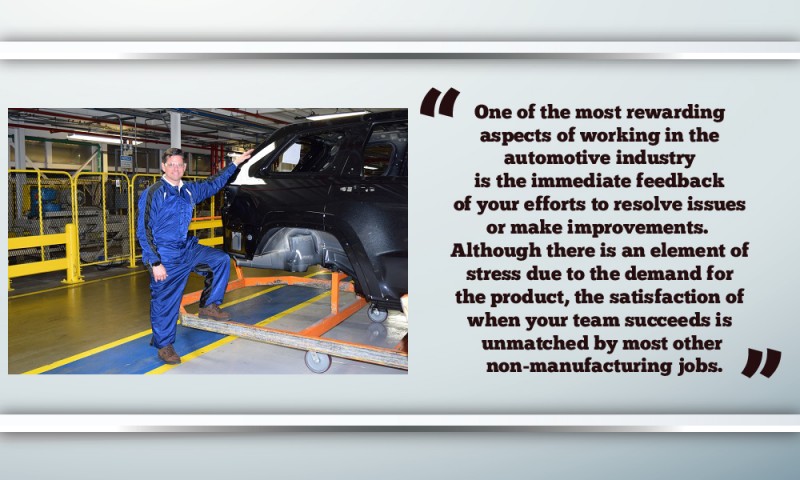

Lloyd Seery is one of those people. He is the Paint Shop Maintenance Manager at Jefferson North Assembly in Detroit, Mich. The plant produces some of the best-selling vehicles for FCA US, including Jeep Grand Cherokee and Dodge Durango. Seery and his team came up with a cost-saving solution to a sticky problem that is not only patent pending, but has also led to a potential industry standard for paint systems.

“My day typically starts around 4:30 a.m. with a quick review of any critical emails or texts from the 3rd shift while the water warms up in the shower. I wish my wife a good day as she heads out for an early morning run and I warm up my car for a quiet 45 minute drive into the city of Detroit.”

“My morning routine includes a quick review of our paint shop status, followed by a review of our previous day’s results. I look forward each morning to placing a green sticker on our build tracker indicating another successful day of meeting our customer’s demands.”

“While leaving the plant is not as easy some days as leaving the “office”, each day is concluded with a hand-off meeting with the following shift to share the day’s challenges and remaining open opportunities.”

“In the evenings, I enjoy spending time with my wife of 28 years. We enjoy the outdoors, running, boating, and spending time with our three children as their busy schedules allow. Our oldest son is in law school, our younger son is an architect and participates in the ‘Challenge Detroit Fellowship Program,’ and our daughter studies abroad (China, Italy, and Ghana).”

“Based on the high demand for the Jeep Grand Cherokee and Dodge Durango, there is a lot of importance placed on making our daily build with high quality. In the past, the paint shop has experienced equipment downtime in the electrocoat system involving the locking and unlocking of our vehicles on the paint skids. The skids help carry the sheet metal body of the vehicle through the tanks where they are sprayed during the phosphate/e-coat process. The skids run about 75 jobs per hour, 20 hours a day, six and sometimes seven days a week.

“One day, we experienced a breakdown with our electric servos. A servo is a small electric motor with a rotating device on the end that is used to rotate the locking mechanism on the skids (there are 4 locks on each skid to lock the body onto the skid). While the maintenance and electrical teams worked to resolve the issue, we had an idea for another solution using the inertia of the skid moving across the transfer table and a stationary steel block to rotate the locks into the unlocked position. Within hours, we installed a prototype un-locker that later proved to be a permanent replacement. Minor modifications were made and an identical plate was installed to replace the locking equipment.

“The patent-pending process has proven to be a significant cost savings and potentially an industry standard for paint systems. As a result of implementing this fix, downtime associated with the locking and unlocking of the skids has been eliminated. The design is being installed in one of our plants in Mexico and will be considered for all new installations.”

- The phosphate/e-coat process

- The vehicle on the paint skids

- The vehicle on the line