The next time you shop for a new FCA vehicle, don’t be surprised if there’s a turbocharged four-cylinder engine under the hood. There won’t be any disappointment, though, as the turbo four matches some larger engines for power while also delivering improved fuel economy.

The change is underway at FCA: The all-new 2018 Jeep Wrangler and restyled 2019 Jeep Cherokee can be equipped with a turbocharged 2.0-liter four-cylinder engine rated at 270 hp.

Even so, FCA Powertrain engineers have their sights on delivering more efficiency without sacrificing performance. Getting there means more pressure (boost) and higher compression ratios. Doing that will generate more heat in the cylinder head, which sees some of the highest temperatures in an internal combustion engine.

A major challenge, though, is overcoming the strength and thermal limits of the aluminum alloys used today for cylinder heads. Those alloys, known as 319 and 356 grades, begin to severely weaken above 200 degrees Celsius (392 degrees Fahrenheit).

Now, a cooperative research effort between FCA, the federally funded Oak Ridge National Laboratory in Tennessee and casting supplier Nemak has created a new aluminum alloy that stays strong up to 300 degrees Celsius (572 degrees Fahrenheit).

In addition to staying strong at higher temperatures, this new alloy can be cast and machined using existing technologies and costs only 7 percent more than today’s alloys – all key goals of the three-year, $3.5-million project sponsored by the federal government under a cooperative research and development agreement known as a CRADA.

This new alloy, known as 16HT or ACMZ, may enable engineers narrow the “bridge” areas in the cylinder head – the areas of metal between the valves, the spark plug and the direct fuel injector. Narrowing the bridges frees up room for larger valves or even a second spark plug, giving engineers the flexibility to tailor an engine for the desired balance of performance and efficiency.

The capabilities and potential uses for ACMZ earned it a spot on R&D Magazine’s widely respected R&D100 Awards in 2017.

Copper is the key

ACMZ has one key difference from today’s automotive aluminum alloys (alloys are a mixture of multiple metallic elements) – it does not use silicon as the strengthening component. Instead, ACMZ uses copper.

Aluminum alloys with copper are not new, explains Gregg Black, senior manager in Advanced Powertrain Engineering at FCA. However, they are expensive, produced in low volumes and haven’t been used in the auto industry due to a tendency for the part to develop small cracks during solidification after casting, an issue known as “hot tear.”

This is where Oak Ridge National Laboratory played an important role. Oak Ridge’s advanced probes let engineers understand down to the atomic level what happens with an alloy as it cools, inspecting the formation, size and location of strengthening elements called precipitates.

Oak Ridge also houses the Titan supercomputer – ranked as the third most-powerful supercomputer in the United States and seventh in the world.

Using a predictive development process known as integrated computational material engineering (ICME), the Titan supercomputer enabled the CRADA team to virtually create 50 never-before proposed aluminum-copper recipes then simulate the cooling and performance properties. It helped the team narrow the field to seven high-potential alloys within 24 months.

“The Titan and ICME let the team focus only on truly promising candidates instead of spending time on trial and error,” Black says. “It’s like Star Wars stuff for us, creating new alloys in the computer without having to pour it.”

Work gives FCA a head start

FCA and its partners have applied for four patents on the new alloy. Because it was developed with government sponsorship, other companies will have the opportunity to use the new material when it becomes commercially available. But being on the ground floor of development gives FCA a head start, Black notes.

Other automakers tackled the aluminum alloy high temperature issue at the same time as FCA, picking their own partners and establishing CRADAs with the government. Those efforts did not use copper as the strengthening agent.

“When we focused on copper, other people in the industry almost laughed us off, saying we’d never be able to cast that,” Black says. “We knew there was competition, including other teams working at Oak Ridge National Labs, but we outperformed everyone on this.”

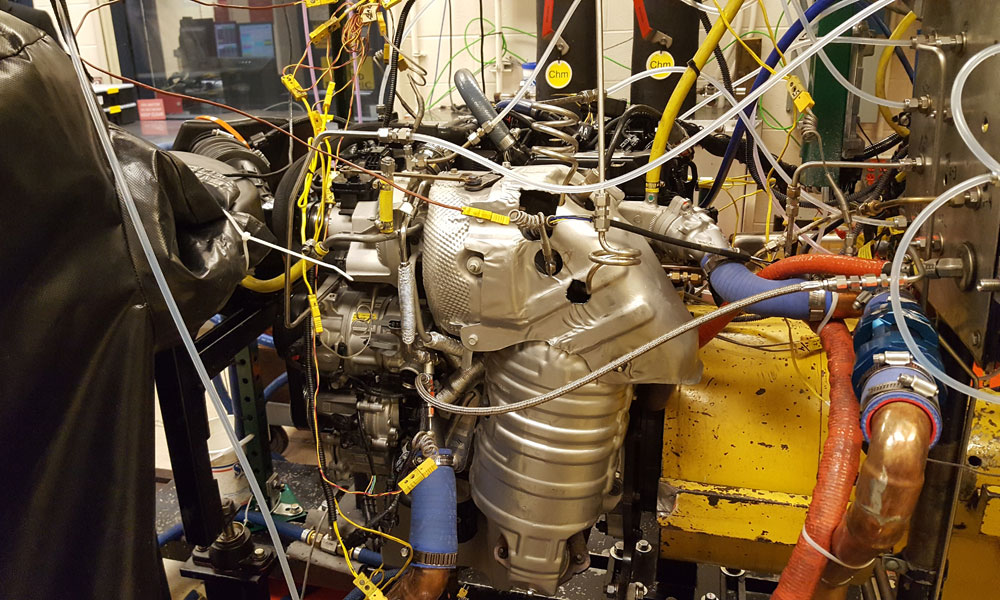

It will still be a few years before ACMZ appears in a production engine. But FCA and Nemak have already cast more than 100 cylinder heads with the alloy, using a current production design, and have put several hundred hours of dynamometer testing on some prototypes.

Also, castings made with ACMZ have been machined on the same equipment used for current production cylinder heads to prove that the new alloy is compatible with today’s manufacturing technology. The only likely change in the manufacturing process for ACMZ involves refining the heat-treatment ovens used after the part is cast, Black says.

FCA powertrain engineers still have plenty of development work to do with ACMZ, documenting its design and performance capabilities to share with engine development teams. The knowledge gained creating ACMZ can also be helpful as engineers look for better-performing materials for other powertrain components.

“We just getting started on the process to create a design now that we have a material that will work,” Black says. “We feel like we really have a tiger by the tail.”